VOC Minimization Packaging Market to Reach USD 2.7 Billion by 2035 — APAC and USA,Drive Low-VOC in Sustainable Packaging

South Korea’s VOC minimization packaging market, estimated at USD 100 million in 2025, is led by solvent-free adhesive lamination with a 43.5% share.

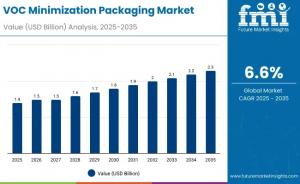

NEWARK, DE, UNITED STATES, November 10, 2025 /EINPresswire.com/ -- The global VOC Minimization Packaging Market is on track for substantial growth, expanding from USD 1.4 billion in 2025 to USD 2.7 billion by 2035, reflecting a robust CAGR of 6.6%. This momentum is largely fueled by stringent environmental regulations, the rapid adoption of solvent-free adhesives, and the ongoing shift toward water-based and bio-based packaging materials. As industries strive to reduce their ecological footprint, packaging manufacturers are prioritizing VOC-free production technologies to align with global sustainability goals.

Driving the Next Wave of Sustainable Packaging

The growing awareness around volatile organic compound (VOC) emissions and their environmental impact is reshaping packaging design and material choices across industries. Governments, regulators, and global brands are enforcing tighter emission norms, compelling packaging manufacturers to transition from solvent-based to low-VOC and VOC-free technologies.

Explore Opportunities – Get Your Sample of Our Industry Overview Now!

https://www.futuremarketinsights.com/reports/sample/rep-gb-27061

Between 2025 and 2030, the market will add nearly USD 0.5 billion in value from the increased adoption of flexible, solvent-free packaging, while eco-friendly inks and coatings are expected to contribute another USD 0.8 billion between 2030 and 2035.

Asia-Pacific (APAC) continues to dominate growth, led by South Korea, which is advancing at an impressive 7.1% CAGR thanks to its proactive green certification programs and R&D investments in low-VOC coatings.

Leading Technologies and Market Segmentation

Solvent-Free Adhesive Lamination Leads the Transition

Solvent-free adhesive lamination accounts for 42.1% of the total market share in 2025, making it the leading technology in VOC minimization packaging. Its wide acceptance stems from high-speed processing, strong adhesion performance, and virtually zero solvent emission—ideal for applications in food and pharmaceutical packaging.

By 2035, continuous innovations in resin chemistry and automation are expected to strengthen the role of solvent-free laminations in global production lines.

Solvent-Free Laminates Dominate by Material

In material segmentation, solvent-free laminates are projected to hold 36.8% market share in 2025. These laminates offer durability, superior bonding, and compliance with global food safety regulations. Their use in flexible pouches and folding cartons continues to grow as companies seek to balance performance with sustainability.

Flexible Pouches – The Future of VOC-Free Packaging

Flexible pouches capture 38.4% of the packaging type segment in 2025 due to their lightweight design, minimal waste generation, and compatibility with solvent-free adhesives. By 2035, innovations in recyclable and bio-based films will further elevate their dominance in FMCG and healthcare packaging.

Food & Beverage: The Largest End-Use Sector

The food and beverage industry leads with 44.2% market share in 2025, driven by regulatory demands for low-emission and food-safe packaging. The push toward sustainable supply chains and VOC-free laminations is reshaping how manufacturers package ready-to-eat meals, snacks, and beverages.

Market Dynamics: Drivers, Restraints, and Opportunities

Key Growth Drivers

1. Stringent Environmental Regulations: Governments worldwide are mandating reduced VOC levels in manufacturing, driving packaging producers to adopt eco-friendly adhesives and coatings.

2. Sustainability Commitments: Brands aiming for net-zero VOC emissions by 2030 are investing in water-based inks, solvent-free laminations, and recyclable packaging structures.

3. Improved Occupational Safety: Low-VOC technologies enhance workplace health conditions by minimizing exposure to harmful solvents.

Challenges and Restraints

• High setup and material costs of VOC-free systems pose financial challenges for small manufacturers.

• Slower curing times for water-based systems compared to solvent-based ones may affect production efficiency.

• Adhesion issues with certain substrates can limit scalability.

Emerging Opportunities

• Hybrid coating systems that combine UV-curable and water-based chemistries show strong commercial potential.

• VOC capture and recycling technologies are gaining traction in industrial packaging lines.

• The integration of digital automation and smart quality control systems is optimizing emission monitoring.

Regional Market Outlook

United States

The U.S. VOC minimization packaging market will grow at a 6.7% CAGR, driven by EPA regulations and sustainability-driven transformations in FMCG and personal care packaging. Companies are replacing traditional solvent laminations with water-based adhesives to meet emission compliance standards.

• Green manufacturing enhances adoption.

• FMCG packaging drives demand.

• VOC-free laminations dominate modernization efforts.

China

China’s VOC minimization packaging market will grow at 6.6% CAGR, bolstered by eco-policy reforms and industrial modernization. Domestic firms are scaling low-VOC adhesive production to replace solvent-heavy materials.

• Green factory initiatives accelerate adoption.

• Industrial packaging drives new investments.

India

India’s growth rate stands at 6.5% CAGR, backed by sustainability mandates and expanding FMCG packaging needs. SMEs are adopting water-based inks and solvent-free laminates to meet export standards.

• Government policy reforms accelerate modernization.

• Eco-friendly packaging gains export momentum.

Japan

Japan leads innovation with a 7.0% CAGR, emphasizing recyclable, low-emission materials for high-value packaging. Advanced coating and adhesive technologies are supporting export-oriented sectors like healthcare and electronics.

• Tech-driven recyclability leads exports.

• Bio-based coatings ensure VOC control.

South Korea

South Korea will register the highest CAGR at 7.1%, driven by its smart eco-packaging systems and green certification initiatives. R&D incentives promote development of bioplastic laminates and advanced VOC-free coatings.

• Green certifications boost adoption.

• Bioplastic laminates dominate production.

Purchase Full Report for Detailed Insights

For access to full forecasts, regional breakouts, company share analysis, and emerging trend assessments, you can purchase the complete report here:

Buy Full Report – https://www.futuremarketinsights.com/checkout/27061

Competitive Landscape

The market is moderately fragmented, featuring major innovators such as PacTec, Constantia Flexibles, Ecologic Brands, Ranpak, AptarGroup, Berlin Packaging, YashPakka, Vegware, EcoEnclose, and TIPA.

• Constantia Flexibles and TIPA are advancing solvent-free laminate technologies.

• YashPakka and Vegware lead in bio-based packaging innovations.

• AptarGroup and Berlin Packaging focus on VOC-free coatings for food and pharma sectors.

Competition is intensifying around sustainability performance, recyclability, and VOC compliance as brands race to meet emission reduction targets.

Recent Developments

• In November 2024, TIPA unveiled its expanded zero-waste compostable packaging line at Pack Expo 2024, featuring new films and laminates designed to reduce VOC emissions and plastic waste.

• On March 4, 2025, Ranpak Holdings Corp. introduced PaperWrap, a plastic-free pallet wrapping solution, reinforcing its commitment to sustainable, VOC-minimized alternatives.

Why FMI: https://www.futuremarketinsights.com/why-fmi

Have a Look at Related Research Reports on the Packaging Domain:

ESD Tapes and Labels Market - https://www.futuremarketinsights.com/reports/esd-tapes-and-labels-market

Multi-Part Labels Market - https://www.futuremarketinsights.com/reports/multi-part-labels-market

Aerosol Valves Market - https://www.futuremarketinsights.com/reports/aerosol-valves-market

Horizontal Strapping Machine Market - https://www.futuremarketinsights.com/reports/horizontal-strapping-machine-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.